In 2004, the School of Chemical Sciences launched a Chemical Tracking initiative with the goal of creating a single, online database containing information on its chemical stores in all of its facilities. The database will serve the research community by streamlining chemical acquisition, providing safety information, reducing redundant purchases, assisting in laboratory organization, and saving researchers both time and money.

All SCS research groups, teaching labs, and service facilities residing in Roger Adams Lab, Chemical and Life Sciences Laboratory-A, Davenport Hall, Chemistry Annex, Noyes Lab, and Beckman Institute are responsible for maintaining their chemical inventory in the Chemical Safety EMS inventory module.

Click here to access the Chemical Safety EMS. If you are a researcher or staff member in SCS working in one of the buildings listed above and you are unable to access the EMS inventory module, don't hesitate to contact SCS Inventory.

The Chemical Inventory Program is the result of the University of Illinois compliance with the Chemical Facility Anti-Terrorism Standards (CFATS), 6 CFR Part 27; requiring institutions to track and monitor usage of potentially dangerous chemicals. It also satisfies regulations and guidelines of other bodies such as the EPA, OSHA, and the University of Illinois DRS.

How it Works

- All containers of chemicals used or housed at the School of Chemical Sciences will have barcoded labels

- The barcodes provide a unique identifier for each container of chemicals in the School of Chemical Sciences.

- Barcodes are linked to a database containing information such as container size, location, hazard information, and a safety data sheet (SDS)

- When a barcoded container is moved to a different location or is disposed of, the database is updated.

Researcher/Staff Responsibility

- Input all incoming containers of chemicals into the database and label each container with its corresponding barcode

- Remove container from database when it is empty or being submitted as waste

- Update database if chemical is being moved to a new location

- If chemicals are being transferred from another research group or facility, contact Shane Brownfield to assist with database update

Proper Container Labeling Guidelines

In the vast majority of situations, a chemical will be entered into the inventory, a barcode will be placed on it, and then will be removed from inventory when the container is empty or being disposed of. The following are some exceptions to this rule:

- Rapidly used and replenished chemicals: The barcode label can be placed on a string tag and attached to the container or on the lid/cap of the container. The tag/lid/cap will then need to be transferred to the new container when the old one is empty

- Deuterated solvents: If all deuterated solvents are stored together in a box/bin, one label per chemical can be created with the upper limit that will be kept on hand and placed on/in the box/bin

What does not need to be Inventoried

- Any chemical that does not have an assigned CAS number

- Samples produced within your lab

- Aliquoted chemicals

- Buffers

- Broths

- Oils

- Silica gel/sand

- Refilled containers

Compliance and Accountability

- Chemical inventories will be audited at least annually. Additional audits can be requested if desired.

- Labs will be assessed on their compliance protocols and the results will be emailed to the group chemical inventory officer and PI.

- End users are responsible for the receiving and disposing of containers.

Getting Started for Users

Chemical Safety EMS is the software package being used to manage the SCS chemical inventory. The Division of Research Safety is also using this software to manage their chemical waste pickups. Both modules are maintained as a single installation so you will use the same login and have access to both systems from the same webpage. The website to access the chemical inventory is https://unillinois.chemicalsafety.com. You will click on the “Illinois Sign On” button on the left side of the page and use your netID and password to log in to the system.

Getting Started with Chemical Safety EMS Inventory

Click here for an introduction to the Chemical Safety EMS inventory system

Adding Containers to Inventory

Click here for instructions for adding containers to inventory

Removing Containers from Inventory

Click here for instructions for removing containers from inventory

Moving Containers to new Locations

Click here for instructions for moving containers to new locations in the chemical inventory

Printing Container Barcode Labels

1. Click on Actions->Labels->Label Generator

2. Look for the label name (UIUC Label) and click the Print button in the corresponding row.

3. Click on the print option you need. Use "Print active record" if you want to print only the label of the container you're currently viewing and "Print current lookup" if you want to print labels for all containers in your current search result.

4. Send generated PDF to the label printer. The preferred method is to open the PDF and print it from Adobe. Printing from the various browser PDF readers can have mixed results. Printing directly from Edge and Chrome currently generates scannable barcodes though there is slight distortion compared to the label printed in Adobe. Printing from Firefox is not recommended as there are formatting issues that currently cause part of the chemical name to be cut off.

Barcode Label Placement Guidelines

The labels that are created for each container are vitally important in maintaining the integrity of the chemical inventory. For this reason, it is essential that all labels printed and attached to the containers do not have any information that is cut off and that the barcode is scannable. If the barcode is unable to be scanned, the inventory reconciliation process takes considerable longer. Please use the following guidelines to ensure that your labels will be complete and that the barcode is able to be scanned:

- Double-check that you are using the 90% custom scale when printing the labels. See "Printing Container Barcode Labels" for instructions about how to do that.

- Check the barcode to make sure there are no breaks in it that would prevent it from being scanned.

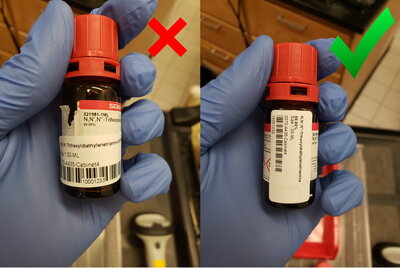

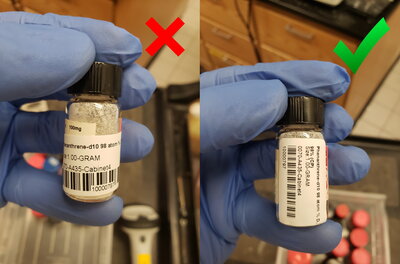

- When placing the label on the container, make sure that the barcode is running along the longest face of the container. Essentially what this means is that if you have a short, wide container, the barcode will be oriented horizontally and if you have a tall, skinny container such as a vial, the barcode will be oriented vertically. This isn't as critical for containers larger than 100 grams or mL as those containers are typically large enough to not cause scanning issues with the barcodes. Such detail is crucial though for small containers. Below are some examples of how the labels should or should not be attached to smaller containers:

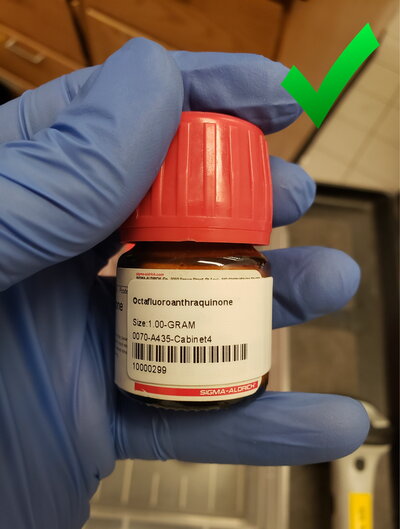

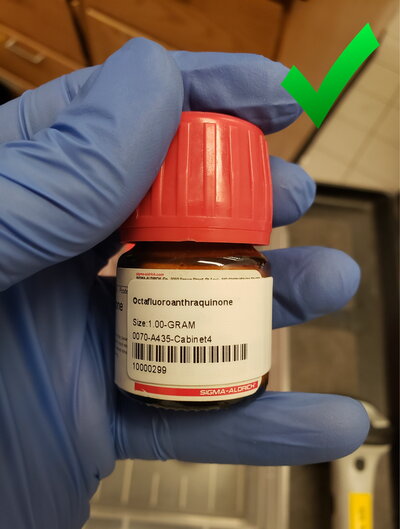

In the case of a shorter container as is typical with 1g and 5g chemicals from Sigma, the label should be attached horizontally:

In the case of a skinnier container, the label should be oriented vertically to prevent wrapping the barcode around the container:

For really small vials, the right side of the label can be trimmed down to allow for easier application:

SCS Chemical Inventory Staff

Shane Brownfield, CCHO

Safety and Inventory Supervisor

16 RAL

(217) 300-6618

sbrownfi@illinois.edu

Andy Benner

Inventory Clerk

16 RAL

abenner3@illinois.edu